What is SCADA?

It is an acronym that stands for Supervisory Control And Data Acquisition.

What does that mean though?

I’ve always found the simplest way to explain something is to find a common topic to relate it to. For example, the TV show “How It’s Made”. Imagine in one of the automated factories on that show, all the robots and computers and operators, and owners. SCADA is the system that sits between all of these.

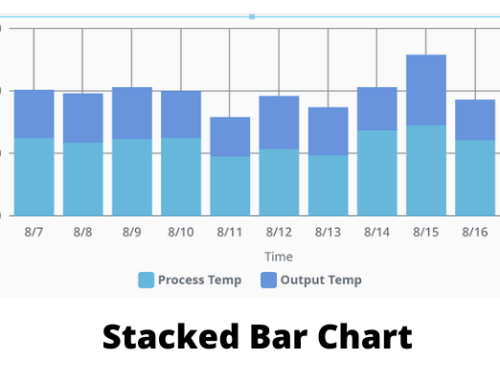

Typically SCADA will involve a central application. This application will provide operators and owners with a visual representation of conditions both current and in the past of equipment on the plant floor. As well this application or suite of applications will provide the ability to not only monitor the equipment but to control it as well.

SCADA systems can be extremely complex gathering hundreds of thousands of data points from thousands of devices or they can be very simple monitoring a single data point from a single device. The data collected by a SCADA system has historically been provided by a PLC, RTU, or other telemetry device(s). Devices such as these are designed to monitor and control various industrial process equipment.

The evolution of Industrial Internet of Things and SCADA

As the Industrial Internet of Things expands evermore to seemingly every possible device on the planet, so has the landscape for SCADA changed. No longer does SCADA need to rely on archaic simple computers to obtain key business data. With the Industrial Internet of Things, the collection of crucial data an organization needs not to survive but to thrive is at their fingertips. Cloud based computing has taken SCADA from a system that was visible only to those in the plant, to a system that can be accessed by anyone, anywhere.

SCADA systems are widely used by industrial organizations all over the world, both in the public and private sectors. They are mainly used to:

- Maintain efficiency in the production process.

- Distribute data that’s later used to make smarter decisions in line with the interests of the company.

- Communicate various system issues to help keep downtime to a minimum.

The success of SCADA systems in so many different kinds of enterprises is mainly attributed to the fact that the systems can be scaled to fit nearly any need regardless of complexity.

Right from their birth in the mid-20th century to date, SCADA systems have evolved such that virtually every place you look, there is likely some sort of SCADA system running behind the scenes. If implemented effectively, they can result in significant savings in terms of time and money. Modern-level SCADA systems allow for data to be accessed from anywhere in the world in real time.

SCADA is the future

This level of global access is unprecedented in the modern world and can allow for corporations and governments to make decisions driven by data to improve operations. The computers do all the difficult number crunching and simply relay the results of these calculations.

Of course, such access levels bears huge security vulnerabilities and serious risk of downtime or data loss should the system crash or be compromised, but most SCADA systems run on advanced SQL databases that are not only easy to scale, but also come with the advantage of industry-grade security and reliability. The utilization of SQL also makes it easier to integrate into existing MES and ERP systems, such that data can flow through the whole organization seamlessly.

By Ben Greenhow